Hot stamping is a popular technique used in luxury packaging to create high-quality, eye-catching designs. It involves transferring metallic or matte foil onto a surface using heat and pressure.

This method is commonly used to add a touch of elegance and sophistication to packaging, such as boxes for high-end products.

Enhanced Aesthetics: Hot stamping adds a shiny, metallic finish or a unique texture to the packaging, making it stand out and catch the eye.

Brand Identity: Custom hot stamping can be used to imprint logos, brand names, or other design elements, helping to reinforce brand identity and recognition.

Premium Feel: The process can give a tactile and visual impression of luxury, which can enhance the perceived value of the product inside.

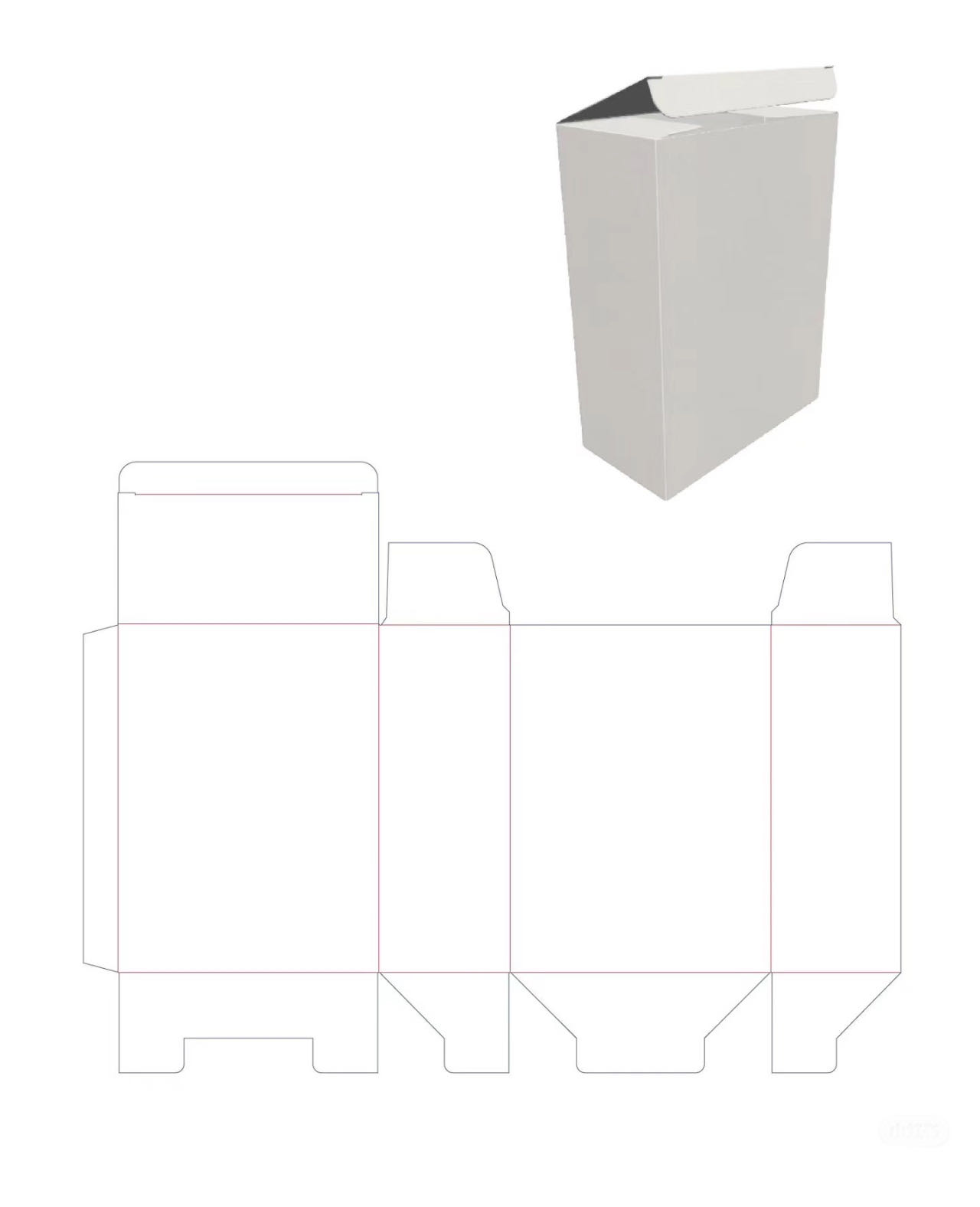

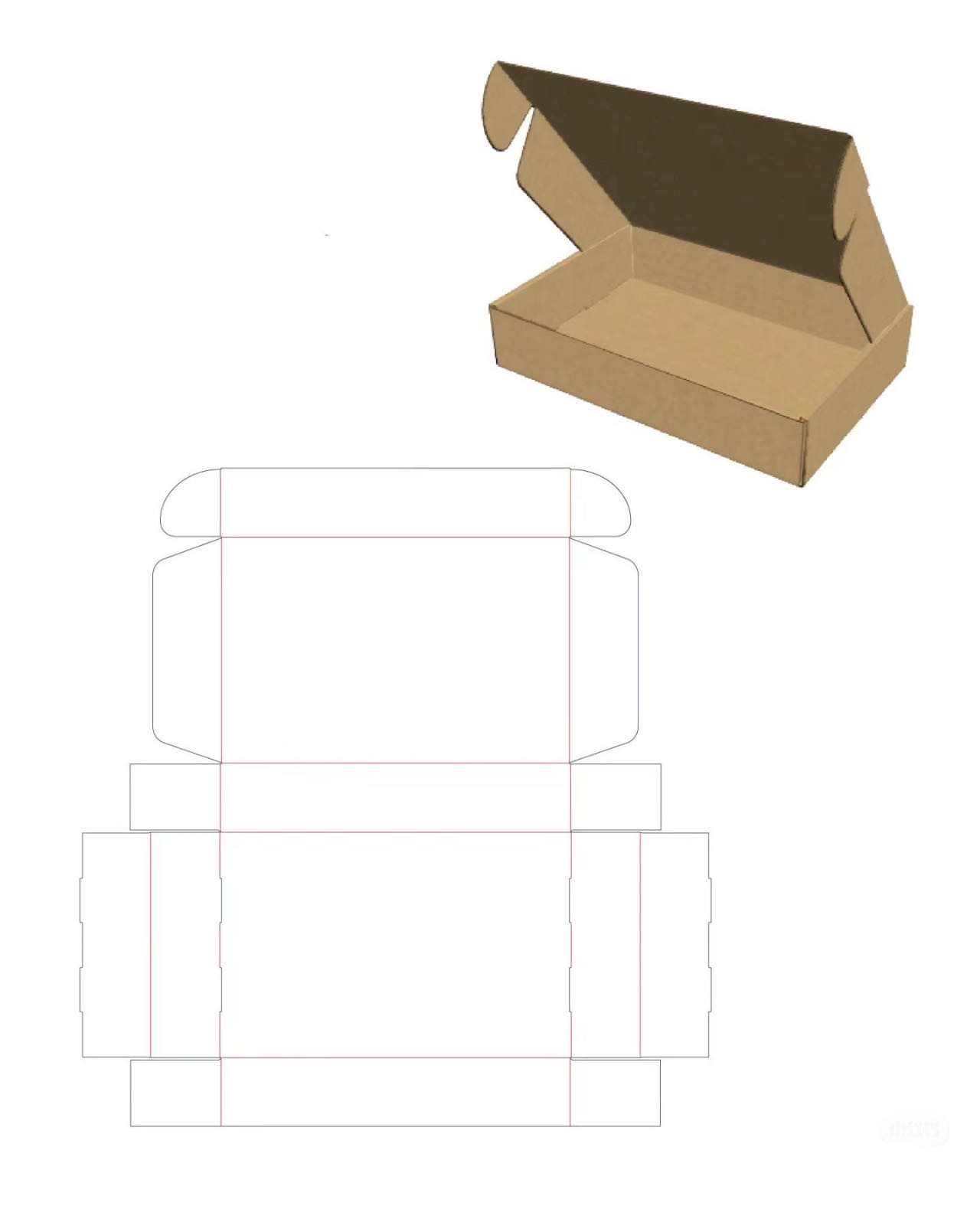

Versatility: Hot stamping can be applied to various materials, including paper, cardboard, leather, and plastic, offering flexibility in packaging design.

Durability: The foil used in hot stamping is resistant to fading and wear, ensuring that the packaging maintains its premium appearance over time.

|

Packaging Materials |

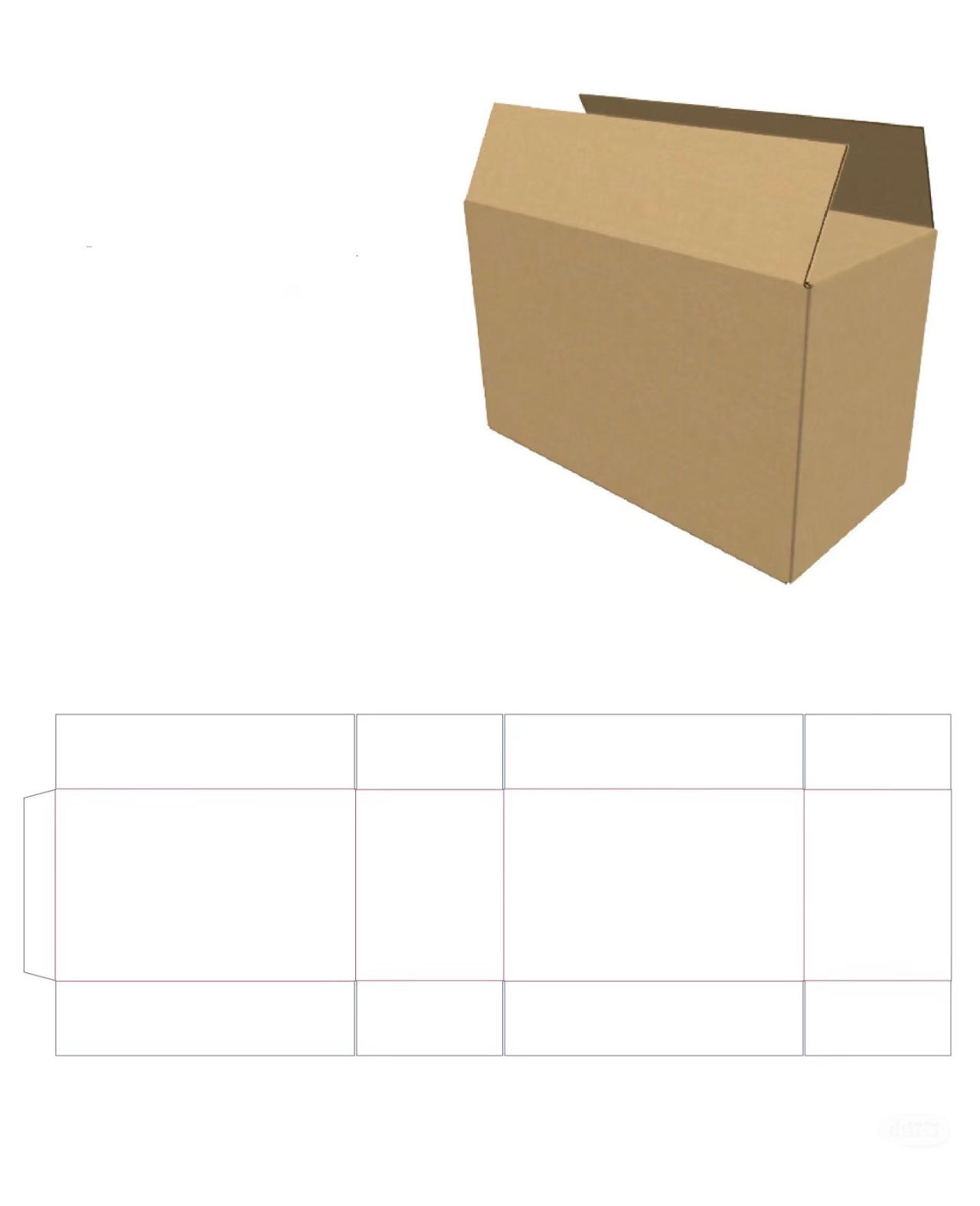

100% Recyclable Corrugated Paper |

|

Paper material |

1.brown kraft paper bag(100g,120g,150g,180g,200g,250g) |

|

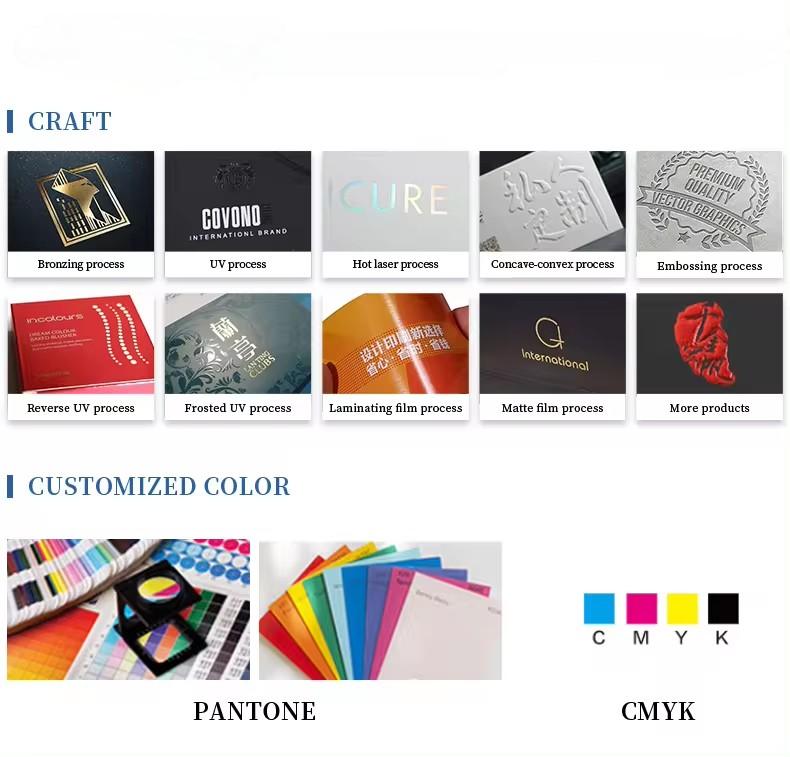

Printing Handling |

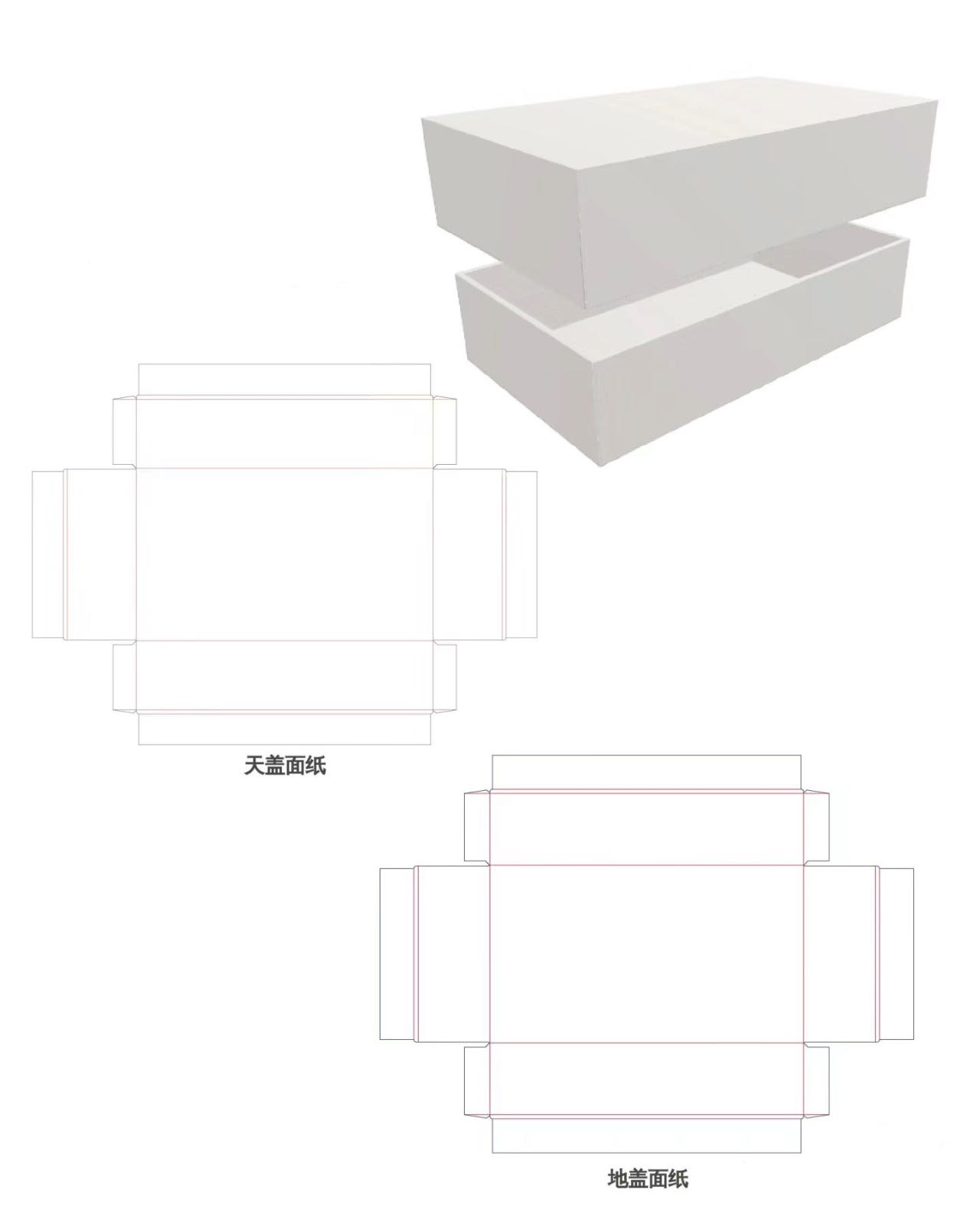

Matt Lamination, Stamping, Embossing, UV Coating, Custom Design |

|

Size(L*W*H) |

According to customer needs |

|

Lead Time |

5 working days for samples; 15 working days for mass production |

|

QC |

Strict quality control under SGS, FSC, ISO9001, and Intertek |

|

Advantage |

Lots of advanced types of equipment in cutting or printing |

Below you'll find answers to some common questions around creating a custom box. If you have more questions, please don’t hesitate to ask anytime!

We have our own factory in Foshan China, close to the port, so we have an advantage in price and quality control.

1. Send inquiries to contact the account manager to request the samples, generally, one or two existing samples could you sent to you for free, if you agree freight collected.

2. The custom-made samples produced are charged according to your requirements; the sample fee will be refunded according to the order amount;

It is usually delivered within 10 to 15 working days after payment and the document is confirmed. If your order is urgent, we will adjust the schedule appropriately and continue to follow up the production process for you.

The general order quantity for a product is 3000pcs. The more the quantity is, the cheaper the unit price will be.

The production lead time is 10-15 days, depending on the order q'ty. The delivery time to Shenzhen Shekou Port is 1day

Guangzhou Baiyun airport